Phase transformation and properties of NiTi alloy

NiTi alloy is a binary alloy composed of nickel and titanium. Due to the change of temperature and mechanical pressure, there are two different crystal structure phases, namely austenite phase and martensite phase. The transformation sequence of nitinol alloy during cooling is parent phase (austenite phase) - R phase - martensite phase. The R phase is rhombic, and austenite is at a higher temperature (higher than the same temperature at the beginning of austenite), or in the inactive state, which is cubic and rigid. The shape is stable. The martensite phase is at a relatively low temperature (less than MF: temperature at the end of martensite) or in a state of loading (activated by external forces). It's hexagonal, extensible, repetitive, unstable and prone to deformation.

Special properties of NiTi alloy

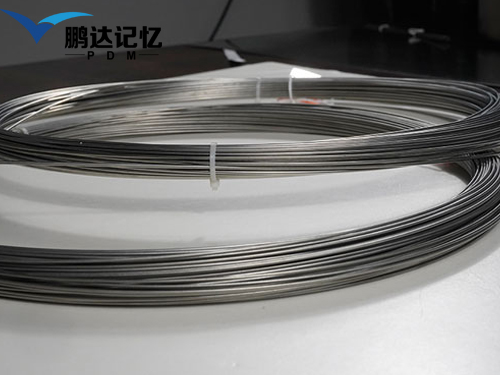

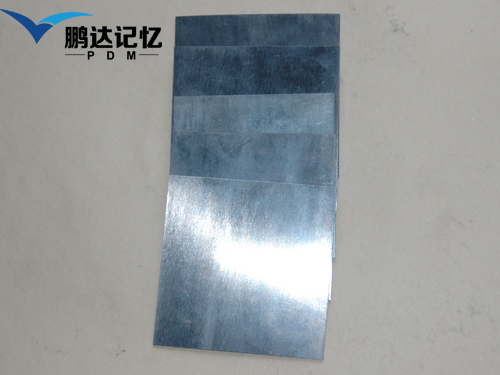

(1) Corrosion resistance: the corrosion resistance of NiTi wire is similar to that of stainless steel wire.

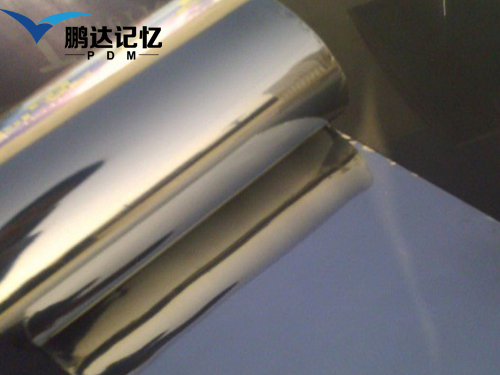

(2) Shape memory shape memory is that when the parent phase of a certain shape is cooled from a temperature higher than AF to a temperature lower than MF to form martensite, the shape of martensite is deformed at a temperature lower than MF, and then heated to a temperature lower than AF, and reverse phase occurs. When you transition, the material automatically restores its shape in the parent phase. In fact, the shape memory effect is the thermally induced phase transformation of NiTi alloy.

(3) Good shock absorption performance: the greater the vibration of arch wire caused by chewing and night molars, the greater the damage to root and periodontal tissue. Through different attenuation test results, it is found that the vibration amplitude of arch wire stainless steel wire is greater than that of super elastic nickel titanium wire, and the initial vibration amplitude of super elastic nickel titanium arch wire is only half of that of stainless steel wire. Arch wire is very important to the health of teeth. Traditional arch wire such as stainless steel wire will increase the root absorption.

(4) The orthodontic ability of stainless steel wire and CoCr alloy dental orthopedic wire is not affected by oral temperature. The orthodontic ability of hyperelastic nitinol dental floss changes with the change of oral temperature. When the deformation is constant. The orthodontic ability increased with the increase of temperature. On the one hand, it can accelerate the movement of teeth, because the temperature change in the mouth will stimulate the blood flow in the stagnant area caused by capillary stagnation caused by the correction device, so that the repair cells need to obtain sufficient nutrition to maintain their vitality and normal function. On the other hand, orthodontists cannot accurately control or measure orthodontics in the oral environment.

(5) Mild orthodontics: currently commercially used orthodontic wires include austenitic stainless steel wire, cobalt chromium nickel wire, nickel chromium wire, Australian wire, gold wire and titanium wire. The load displacement curves of these orthodontic wires under tensile test and three-point bending test conditions. The nitinol unloading curve platform is the lowest and flattest, which shows that it can provide the most durable and gentle correction capability.

(6) Anti toxicity: the special chemical composition of NiTi shape memory alloy, namely nickel titanium and other atomic alloys, contains about 50% nickel, which is known to have carcinogenic and carcinogenic effects. In general, the act surface layer is used as a barrier layer in titanium oxide, which makes Ni Ti alloy have good biocompatibility. TixOy and tixnioy in the surface layer can inhibit the release of Ni.

(7) The so-called hyperelasticity refers to the phenomenon that the strain produced by the specimen under the action of external force is far greater than the elastic limit strain, and the strain can recover automatically when unloading. In other words, in the parent phase state, stress-induced martensitic transformation occurs due to the effect of applied stress. Therefore, the alloy exhibits different mechanical properties from ordinary materials, and its elastic limit is far greater than that of ordinary materials, and Hooke's law is no longer followed. Compared with shape memory properties, hyperelasticity does not involve heat. In a word, hyperelasticity means that the stress will not increase with the increase of strain in a certain range of deformation. Hyperelasticity and hyperelasticity can be divided into hyperelasticity and hyperelasticity. In the stress-strain curve of the former, the stress and strain are almost linear. Nonlinear hyperelasticity refers to the results of martensitic transformation and its inverse transformation caused by stress during loading and unloading in a specific temperature range higher than AF. Therefore, nonlinear hyperelasticity is also called phase transition pseudo elasticity. The pseudo elasticity of nitinol can reach about 8%. The hyperelasticity of nitinol alloy can be changed with the change of heat treatment conditions. Above C, hyperelasticity begins to decline.

current location:

current location: