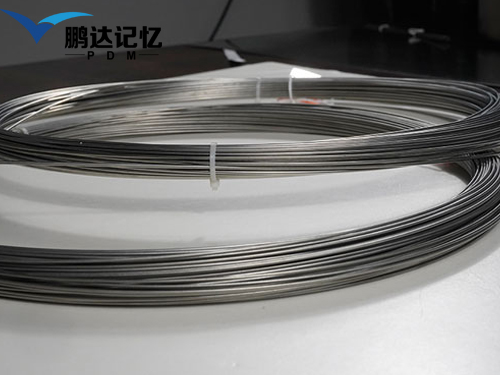

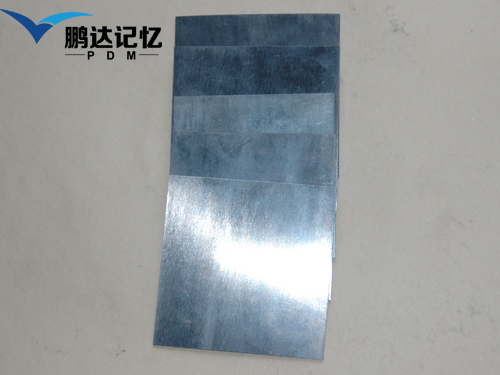

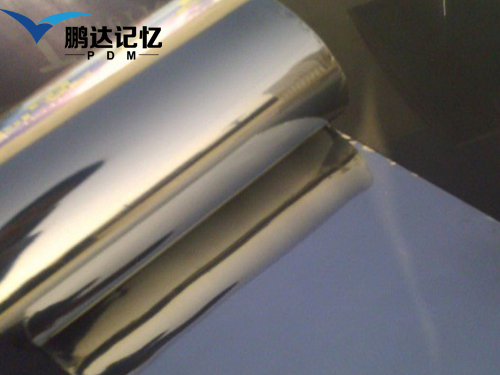

Nickel-titanium memory alloy wire is one of the most important and widely used alloys in shape memory metal. Due to its unique memory recovery properties, hyperelasticity, fatigue resistance and biocompatibility, it has been used in aerospace, livelihood, medical and other industries. Nickel-titanium alloy consists of nickel and titanium, with a ratio of about 50%. According to the ratio of alloys,Forming process and heat treatment control can adjust the phase transition temperature and mechanical properties of the alloy according to different applications.

Shape memory alloys will deform at low temperatures. A material that restores its predeformed shape when the temperature exceeds the critical temperature. In addition to its memory properties, the alloy is also extremely resilient and earthquake resistant, so it is increasingly used in aviation, people's livelihood, energy and medical fields. Shape memory alloys include nickel-titanium base, copper base and iron base.

Niti gene has become an important and widely used alloy for its excellent stability, fatigue resistance and biocompatibility.

The production process of Nitinol memory alloy wire is to melt the Nitinol alloy with a weight ratio of nearly 50% through vacuum smelting technology, and then to make different sizes of Nitinol pipe/line/profile through extraction line/pipe process, and then to adjust through heat treatment technology to determine the mechanical properties and memory temperature range of the material. If I re-executeThe storage processor can restore the storage shape above a certain temperature.

current location:

current location: