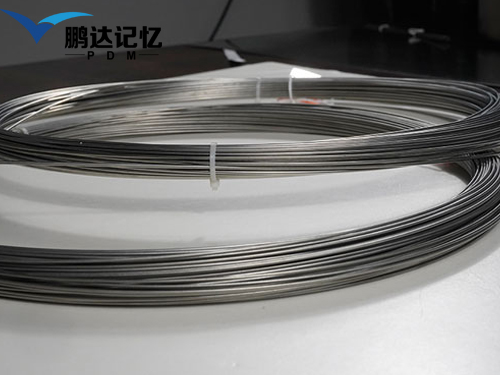

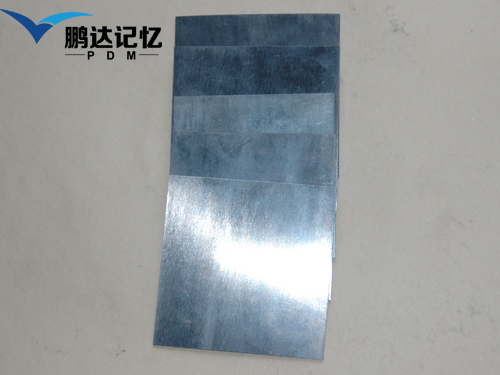

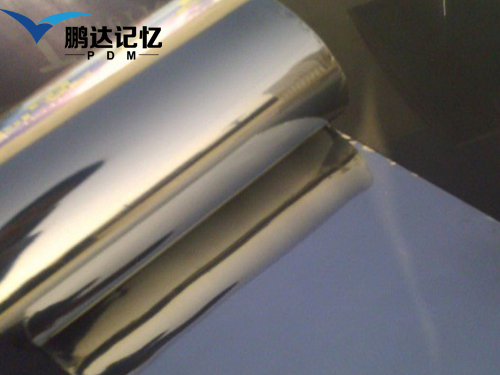

The spring is made of TiNi shape memory alloy wire, which uses the one-way memory effect of shape memory alloy. After stretching, with the increase of temperature, the temperature sensing driving element can recover its original length. The spring is also a typical structure of shape memory alloy element for industrial use. After stretching, take hot water or hot air as the heat source, the temperature of returning to the original length is 65 ℃ - 85 ℃, and the original length is 80mm. The martensitic phase (i.e. the phase structure at low temperature, in this case, the low temperature refers to room temperature) of shape memory alloy is soft phase, and the parent phase (i.e., the phase structure at high temperature, in this case, the high temperature refers to 65 ℃ - 85 ℃) is hard phase.

Purpose:

Memory alloy is widely used. For example, mechanical fastening pin, pipe joint, fire alarm on electronic equipment, plug-in parts, soldering of integrated circuit, artificial heart valve, spine straightening rod, skull repair and reshaping, oral tooth correction and jaw repair operation. It will also play a magic role in communication satellites, color TV sets, temperature controllers and toys. It will also become a new type of material memory alloy in modern navigation, aviation, aerospace, transportation, light textile and other fronts, which has been used in pipeline combination and automatic control. The sleeve made of memory alloy can replace welding. The method is to complete the tube end at low temperature After heating, the sleeve shrinks back to its original shape, forming a tight joint.

current location:

current location: