Mechanical application of memory alloy

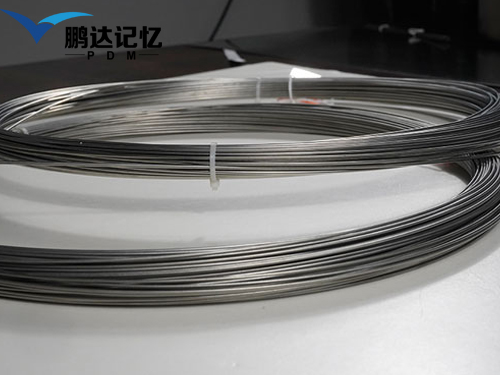

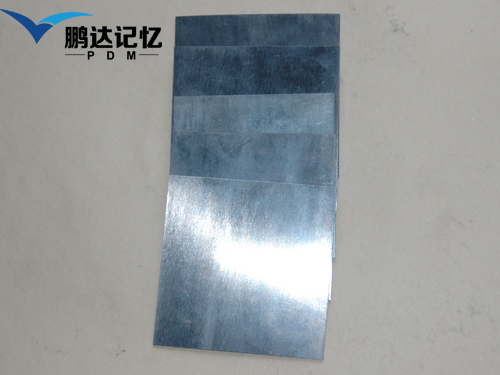

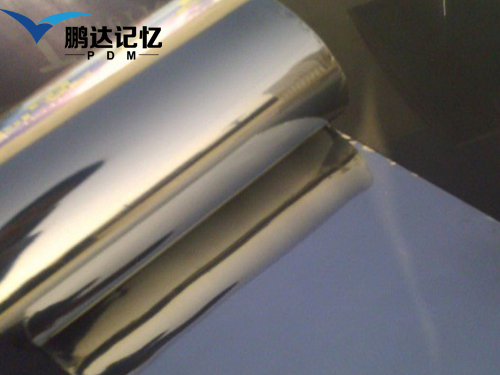

Memory alloys are widely used. Examples include mechanical fasteners, pipe joints, fire alarms for electronic equipment, connectors, welding of integrated circuits, artificial heart valves for medical purposes, spinal rods, skull prostheses, dental prostheses, and jaw prostheses. It will also play a magic role in communication satellites, color TV sets, temperature controllers and toys. It will also become the forefront of new materials such as modern navigation, aviation, aerospace, transportation, textile and so on. Memory alloy has been used in pipe combination. Like automatic control, the sleeve made of memory alloy can replace welding by fully expanding it by about 4% at low temperature. Once the socket and spigot are heated, the sleeve will shrink and form a tight joint. The hydraulic systems of U.S. Navy aircraft have used 100000 of these connections and have not suffered oil leakage or damage for years. The damage of ships and submarine pipelines can be easily repaired by using memory alloy fittings. In some inconvenient parts, the pin is made of memory alloy and heated in the hole. The end of the pin will automatically separate and curl to form a single-sided component.

Memory alloy is especially suitable for thermomechanical and constant temperature automatic control. It has been made into an automatic opening and closing arm at room temperature. It can open the ventilation windows on sunny days and close them automatically at night when the room temperature drops. There are also many designs for memory alloy engines that can operate at very low temperature differences between the two media, opening up new ways to utilize industrial cooling water, waste heat from nuclear reactors, ocean temperature differentials, and solar energy. The common problem is that the efficiency is not high, only 4%? 6%, which needs to be further improved.

current location:

current location: